For the mold release agents(mra) (mold releaser or mould release agent), in modern industry, it is not strange to be applied kneaded silicones.

Mold release agents are a vital part of the process in manufacturing new items and creating products using molds. These chemicals, which are used in automotive and construction applications as well food packaging or consumer products, form the basis for many industries. The mold release agents assist in easy removal or to make obtain the final product after molding without any sticking so that a smooth lamination process is carried out during production and fabric defects are also reduced. Proper mold release agent selection and usage can greatly simplify the manufacturing process, increase product quality (since it is easier to provide a better surface finish) environmental sustainability as well cost efficieny. In this, we are going to explain 5 necessary things which enforce multiple mould release technology in our industrial age.

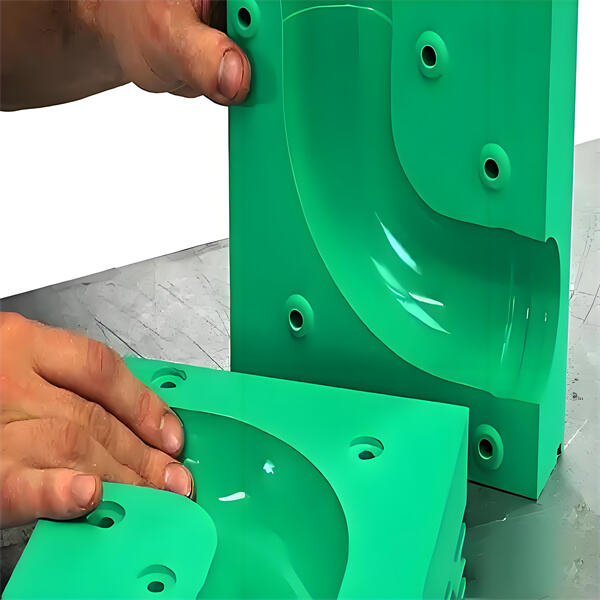

As, to manufacture large volume in short time releasing the products from molds should also be done quick hence manufacturing is directly associated with it. It does this in a variety of ways, and each is specialized by the materials as well processes. VOC-Agency Liquid mold release options are more environmentally friendly than the older solvent materials and they generally provide a healthier working environment. That's true, because solvent-based agents are the most efficient but at a high price: they destroy the environment and must be used with caution. Semi-permanent coatings, applied repeatedly instead of only a single time to enable better anchorage with the mold surface thereby enhancing release properties while reducing reapplication frequency and cycle times. Of course, negative release performance is a deal-killer for critical applications like composites manufacturing since the double-sided precision typically doesn't allow much room for error-in terms of ensuring dimensional stability and surface finish-yet while something as straightforward as an aerosol or spray-applied not only offers good coverage by just-in-time delivery straight onto tooling where it's needed most.

The mold release agents completely changed several industries by allowing manufacturers to create complex figures, previously hard or impossible. They make it possible to manufacture lightweight that is as strong, if not stronger than traditional aerospace and automotive parts but also consume less fuel, whilst increasing life span. These compounds are widely used in the construction industry to enhance appearance without compromising strength by creating intricate precast concrete designs. Mold releases, by contrast, help a company save money in improved scrap rates and productivity; they are more of an operating profit than the razor thin margins suggest.

Choosing the perfect mold release for your project is a tough balancing act of material compatibility, what it needs to do in processing versus how that compares with end use requirements. The substrate material (metal, plastic, rubber or composite), the molding temperature and which surface finish is needed. Understanding sacrificial, semi-permanent and hybrid systems release is critical. The importance of testing the compatibility correctly is then necessary so that no reactions with our substrate or any post-processing treatments occur just before real scale-up. It is based on the environment aspects above all that can be durable, by observing through laws are passes from it. If these criterions are evaluated properly, manufacturers can get their hands to an ultimate mold release solution.

Sustainability requirements make green release agents the ultimate in cutting-edge - prompting this cry for help from customers. Bio-based and biodegradable options that reduce the environmental footprint without compromising performance, Green. The green variant tends to include cleaner-or at the very least, some more sustainable-ingredients, and less (or zero) petrochemicalogen-based foundation materials. Opting for the greenest answers possible helps companies show a bit of corporate social responsibility and serves to satiate what is very quickly becoming an ever-growing part as people seek out ecologically sound produce. In addition, precision application technologies that enable us to use things instead of more universalized and minimized consumption also reduce waste because they adjust how we use in real time which enables debris A circular economy model at manufacturing speed.

top sales are aided by efficient service program which mold releasetechnical assistance all aspects of company, including the formulation a program, choosing materials projects landing, after-sales support.

We specialists in use of composite mold releaseas well diverse production methods, which allows us assist educate our clients produce optimal results from their products.

Many thousands mold release conducts global business through licensed brands. assure the authenticity every product, adhere to the idea brands.

are well-versed in international hazardous mold releasestandards and are able export Categorization 5.2 hazardous substances, includes temperature-controlled substances.