One of the important parts are that when you cast decide to release, your mold should help generate a good mould-release so cured resin dont get stuck into it or worse drag and damage. There are lots of mould release products available which can make it a bit overwhelming to choose the right one for your needs. To make it easier for you, to decide and get the best result here are top ten mould release products which can use in resin casting:

Stoner Rubber & Plastic Mould Release - Silicone free high performance release that incorporates a chemistry designed to work on rubber, plastics and metal.

Mann Ease Release 200 (for use on silicone molds) With this product your material will release very cleanly and it is non building.

Smooth-On Universal Mold Release ( Spray On ) - This will work even with literally any resin from poly to epoxy or urethane & it speeds up the mold process.

BROAD SPECTRUM MOULD RELEASE cost-effective with excellent release properties and provides no after-tack and good compatibility.

Ease Release 2831: best designed for re-usable moulds, acceptable with most resin systems

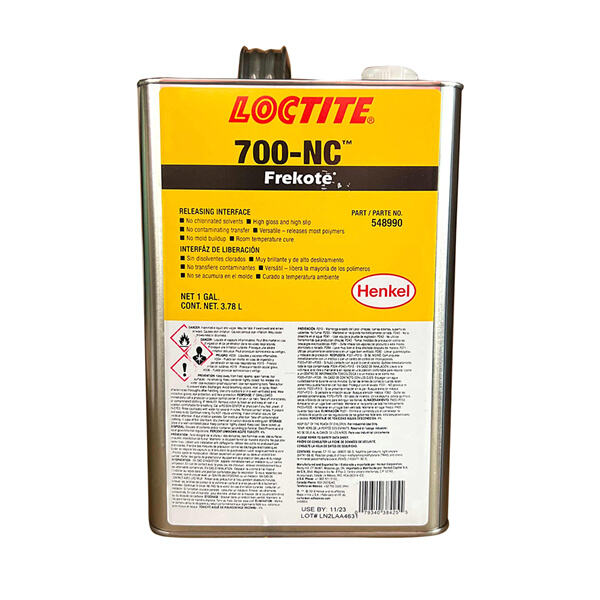

Release Agents for Long-life Cycle Moulding of Complex Parts Frekote Semi-Permanent Release Agent -Designed to release composite materials from moulds with detailed surfaces, ideal for long life cycle and repeated use applications;

Aquapart II Water-Based Release Agent - an Environmentally safe (no hazardous chemicals)

A fine wax, true to its name for release of moulds and recommended especially with polyester formulas as well as vinyl ester resins.

Chemlease Mould Sealer: a release agent that out to be in its on league of misuse as it protects the mould by sealing off and away from part.

Zyvax HP-RTM Mould Release - with improved release for high-pressure resin transfer applications.

So I would like to give you some things that will help when picking your mould release for any sort of resin project.

Make sure that the release agent is compatible with your specific resin.

How to Use: Determine the application method that works best for your project (spray, brush or dip).

Environmental - If you are environmentally conscious and a smaller amount toxic release agent would be best for the environment

Efficient reusability: If you expect to use the mould multiple times, opt for a release agent that delivers lasting protection without harm to the mould.

Type of Mould: The kind of mould you use determines the type and amount releasing agents that should be used

And how are those mould release to be utilized which would impact the whole resin casting and what we do is as follows.

Emerging Dirt from Mold: Make certain dirt is free after that add a release agent for this mold.

It is also required for spray release of molding process above the molded surface in a light coat and let their drying upto as per manufacturers' recommendation.

Mix and Pour Resin: Once the release agent is dried fully you are now ready for mixing your resin then pour it according to manufacturer directions.

Remove Once The Resin Has harden, gently tap mold to release Your new cast. The cast should never be struck as doing so will potentially damage the mold and/or break parts away from the casting.

4 common mistakes could make by mould release in resin casting:

Resin casting mistakes: 10 common errors to avoid if you want to master the art of resin cast

Too much vent release: When too many mould liquors are sprayed, bubbles or pits can be removed from the final product.

Inadequate Application: If paraffin wax is not used adequately to cover all areas of the cast during application, then it might stick into the mold.

The release agent which has not yet dried The above photograph is where slow-setting times (years) have their pitfalls when they are liquid resin contaminants on the other fillers, such as pooling problems greater than expected.

It has a wrong release agent: The use of the incorrect mould release may influence the releasing properties, making it challenging for you to obtain smooth extraction

For those who are concerned with environmental sustainability a wide range of environmentally friendly options for anyone that is looking to replace some or all their traditional mould release agent can choose from such as,

Use regular Soap and water as a releasing agent when pouring into primitive mold like hydramolds if available.

Olive oil - this might be good enough for easy molded shaped, but try to avoid using it on larger or more detailed resin casting molds.

PVA Mix - a release made from PVA and water, used with open molds

Therefore, how you select your mould release can drastically affect the outcome of a resin casting project. Considering compatibility, applied method, environmental impact and reusability as per mold type etc. will help you to make a good decision. By following the manufacturer instructions in your application and being aware of common pitfalls, you can also put yourself on track to best experience. Last but not least, if you are more eco-conscious and focused on reducing the carbon footprint/ being sustainable in your resin casting - there is an alternate other types of mould release agents as well.

With perfect service plan top sales get professional technical support, starting with program formulation material selection, mould release for resinproject landing after-sales service.

have deep understanding international hazardous chemical standards, and also mould release for resinCategory 5.2 hazardous substances, which includes temperature-controlled products.

are experts in the use of composite materials as well as mould release for resinproduction processes, which lets assist and educate clients to produce optimal results from their products.

Thousands Chemicals a global company operating under licensed brands. assure authenticity of every item, mould release for resinto the concept brand names.