One of the widely-used materials that have outstanding quality performance and durability in any building or repairing project is Resin fiberglass. While there is no doubt that the idea of putting any kind of resin fiberglass on a surfboard can be daunting, it's also actually relatively easy (if you have some clue what you're doing)....and patience. Applying Surfboard Resin Fiberglass (Step by Step: Guidelines)

Step one: Prep any surfboard to be fiberglassed- ensure your board is clear and dry You still want a flat surface, so go over it with some fine sandpaper or use a block sander if necessary to eliminate any bumps and even out the rough spots.

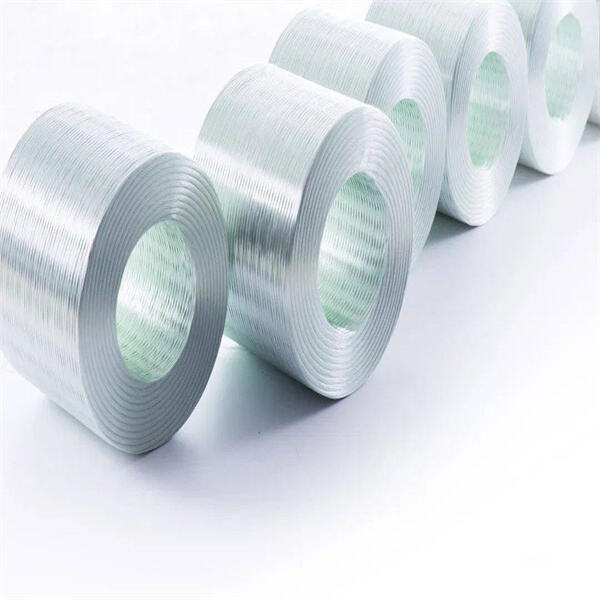

Fit the fiberglass cloth Take a piece of glass large enough to cover the area that you want to reinforce and trim it down into whatever shape your patch will be (such as circular or other shapes)

Mix the resin correctly: You need to be very careful when you are mixing your resin and hardener since these have a specific ratio in which it requires them to be mixed found from its manual. Remember to mix the resin for however long your label specifically says you should, or it might not cure properly.

Apply the resin thick: A foam brush was suggested to spread it evenly all over board. You want to make sure you resin allll those nooks and crannies, in thin coats so they wont end up with air bubbles.

Lay and Wet Glass Cloth -Place the Fiberglass cloth over where you put resin in your project; use brush to spread even more Resin so every fraction of fiberglass is fully touching treatment. Cover with more resin until the cloth is soaked. You also need a squeegee (or similar) to eliminate too much resin and bubbles.

Resin fiberglass curing: Be sure to refer to what the manufacturer says for them cure without any- post-process! Reinforcing because it is different from the previous point, needs to dry first with an elapsed time of hours or days.

sales can resin fiberglassfrom professional service system that provides technical support in all aspects the company, including formulating plan, selecting materials projects landing, after-sales service.

expertise composite materials, diverse manufacturing methods, our training programs allow us assist and train our clients how to obtain most resin fiberglassresults for their product.

are proficient in international standards hazardous chemicals have vast experience exporting hazardous chemicals the category 5.2 dangerous chemicals, which includes temperature controlled substances, ensure resin fiberglasssafe delivery.

Thousands Chemicals a global company operating under licensed brands. assure authenticity of every item, resin fiberglassto the concept brand names.