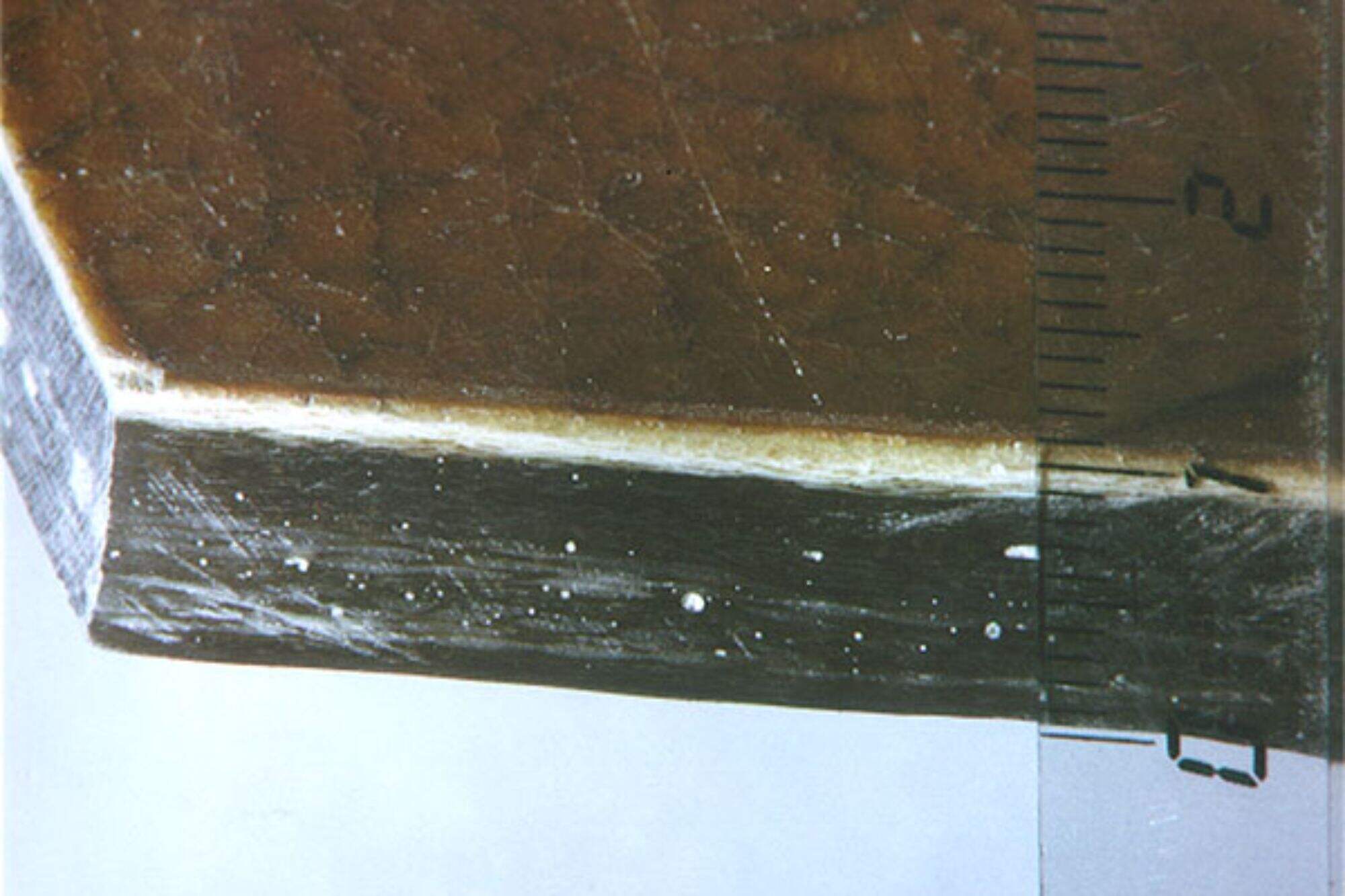

Recently, a striking technological innovation has caused a stir in the field of pipeline engineering. This innovation involves the use of DERAKANE 411 resin in the manufacture of caustic soda pipelines and is expected to operate safely in high temperature environments for up to 15-20 years, bringing a revolutionary change to the industry.

DERAKANE 411 resin has long been known for its excellent corrosion resistance and high temperature stability. This time its application in caustic soda pipeline manufacturing has undoubtedly brought unprecedented technological breakthroughs to the caustic soda industry. Based on the latest research data and experimental results, these pipelines are designed and manufactured to cope with the transportation of caustic soda at different temperatures and concentrations, with an impressive safe service life.

It is understood that these caustic soda pipelines made of DERAKANE 411 resin are expected to be able to operate safely within 10 years. First, in the first 5 years, these pipelines will withstand caustic soda at temperatures between 50-0°C, and in the subsequent 5 years they will face caustic soda at 80°C with a concentration of 10%. What is exciting is that based on advanced technical testing and simulations, these pipelines are expected to exceed expectations and withstand the challenges of high-temperature caustic soda, and are expected to extend their service life to 15-20 years.

A project manager said: "The application of DERAKANE 411 resin allows us to achieve unprecedented long-term safety in the transportation of high-temperature, high-oncentration caustic soda. This is not only a technological innovation, but also a major improvement in industry safety standards."

The launch of these pipelines has not only attracted widespread attention from industry insiders, but has also been highly praised by the international engineering community. This technological breakthrough is a milestone for the caustic soda industry and provides important reference for future pipeline design and material selection. At the same time, the successful application of DERAKANE 411 resin also demonstrates the potential and innovation capabilities of material technology in solving industry challenges.

With the continuous advancement of technology, DERAKANE 411 resin has broad application prospects in high temperature and corrosive environments. This landmark success story undoubtedly opens up new possibilities for the development of materials science and innovation in the field of engineering, and also provides a more reliable guarantee for safe transportation and sustainable development.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

HY

HY

AZ

AZ

KA

KA

LO

LO

MN

MN

MY

MY

KK

KK

SU

SU

TG

TG

UZ

UZ